Manufacturing companies in Mexico are losing thousands of dollars each month because of the long response time to solve daily problems that stop their production lines.

99% of factories in Mexico have their manufacturing machines and software tools disconnected from each other, generating data silos and slowing down problem awareness and response time.

Eliminate these data silos so information can flow between departments to speed up problem awareness and solutions. To accomplish this goal, we developed a Device + App + APIs to collect data in real-time from any manufacturing machine and software to sync production data across the entire factory.

As Co-founder and product designer at D&D Labs, I was responsible for researching and identifying problems that replicate across our customer base and target market. To accomplish this goal, I focused on qualitative research, prototyping, and validating new features.

The first step was to get a deep understanding of why manufacturing companies were having slow response time. The goal we established was to identify the most recurring and time consuming problems that slowed or stopped the production lines. To understand this my team and I settled on three qualitative research techniques to answer the following questions.

Because we already had customers, and talked to them on a daily basis. We already had heard about some of the problems they were facing and naturally each member of the team already had an idea of how to solve them. So we needed to be extra careful about confirmation biases.

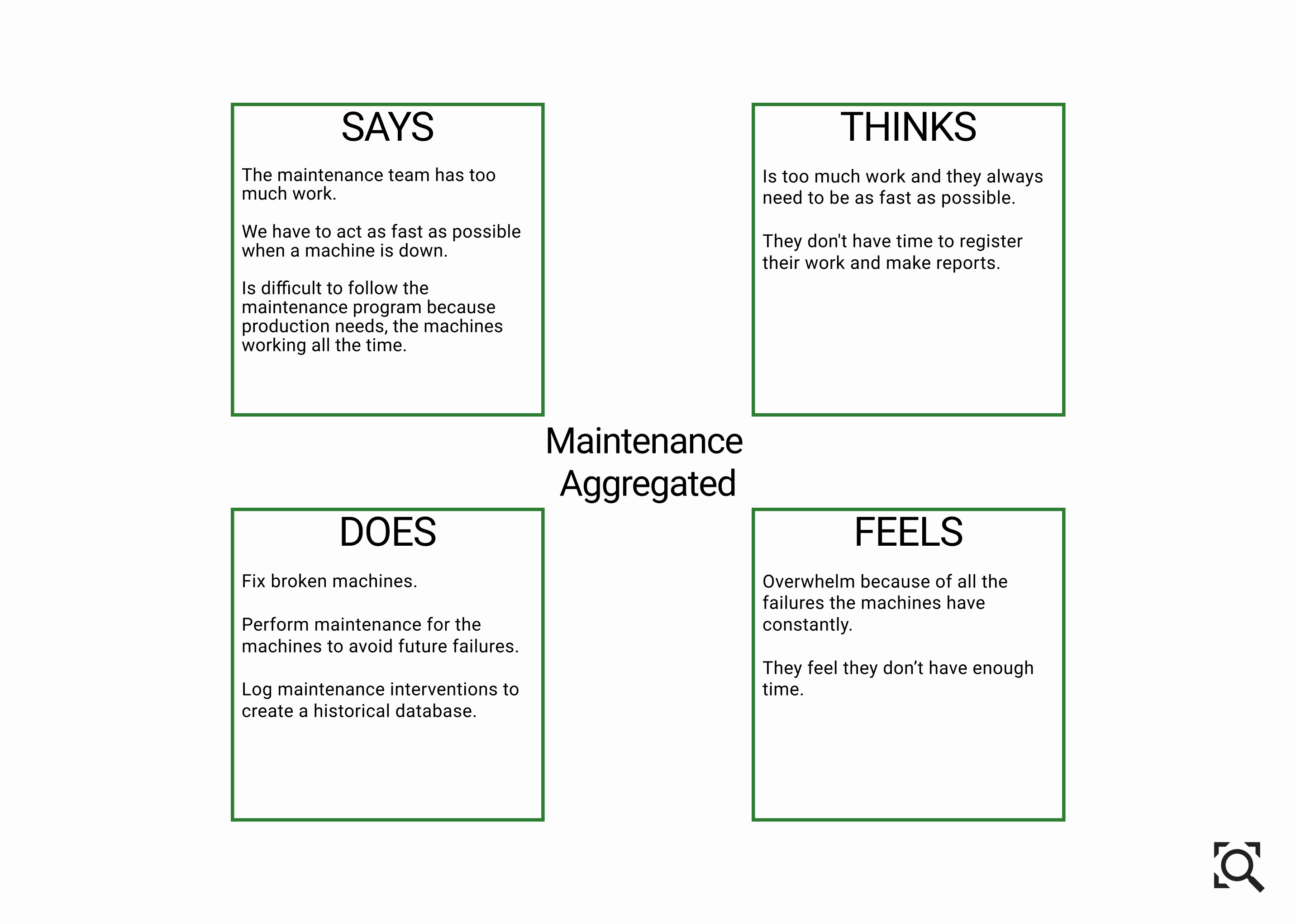

Our goal was to define our end user and other users involved around the problem. This step was very difficult because there were a lot of people involved. To understand this we repeat the same strategy of 1 to 1 interviews we used on the discovery phase.

We looked deeper into the production department and we found two key problems.

Now that we know our end user and their pains, we were ready to think about solutions. We decided to do lightning demos to pump our creativity, make sure we consider every idea and speed up the ideation process.

In the prototyping phase I was responsible for the designing our web app. Because it was a big project I make sure to test the design with real users in every step from initial sketches to final prototype.

.gif)

At this point my team and I realized that we made a big mistake, we didn’t need to design a completely new software solution that covered the functionality of other solutions. What we needed to do was to update the information in their existing tools automatically and in real time.

After this new insight we changed our product to a Device + App + APIs to collect data in real time from any manufacturing machine and software to sync production data across the entire factory and speed up problem awareness.

After launch, I took the task of designing and implementing the analytics infrastructure that will help us identify future improvements. I decided to implement the following tools.

This was a very challenging project because of the multiple users and stake holders involved around the problem. The perspective of a person that deals with the problems of the production line on a daily basis was very different from the perspective of a factory manager. Ultimately I think we made the right decision in prioritizing the production team instead of other teams. In my opinion the biggest mistake we made was not to open our research to more factories earlier in the processes.

If you found something interesting about my work, have any questions or would like to chat, feel free to contact me through any of these channels. It would be a pleasure to help!